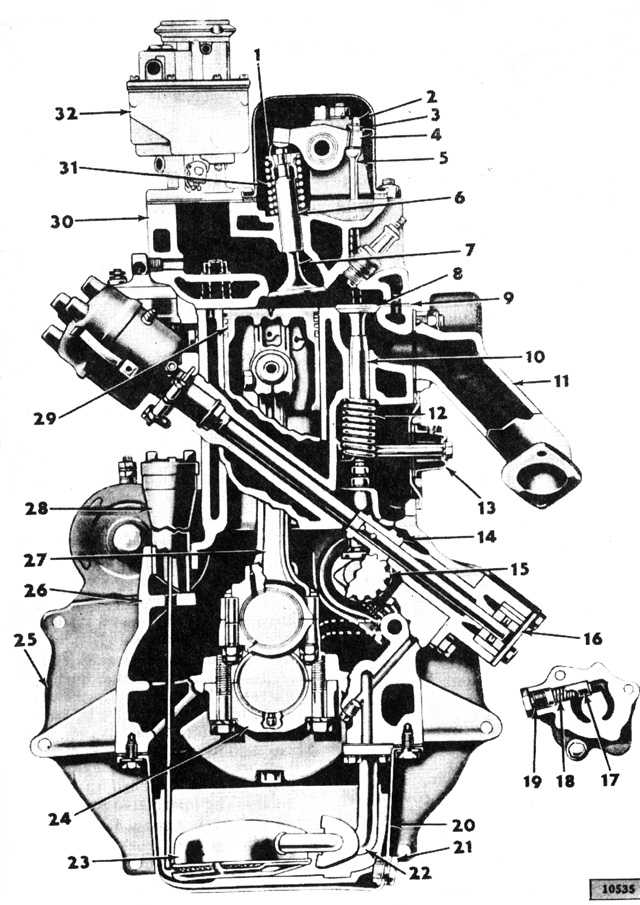

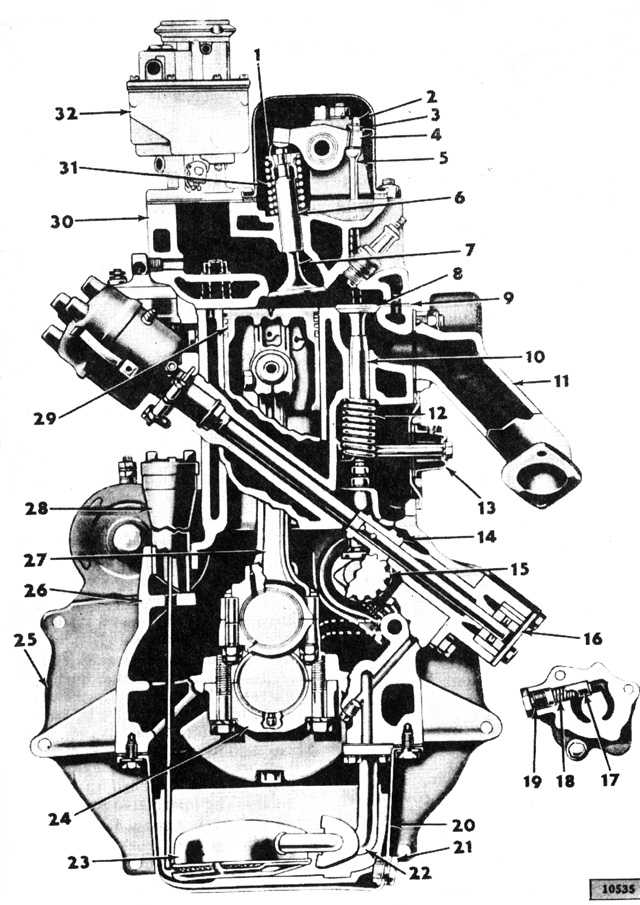

| F4-134 'Hurricane' |

|

|

| This diagram is from the Service Manual for 'Jeep' Utility Vehicles. |

I have not rebuilt my F4-134 engine, but I have done about as much as can be done without a total rebuild. In July of 1997, the crank broke. I can't figure out why it broke. It just fractured right through the journal of the rear main bearing.

I got a crank from an L4-134 (yes they are the same) and made a new Jeep friend. Eric Lawson, who has created Rebuilding an F-head Engine web pages for the The CJ3B Page and happens to live in Phoenix. I got an old crank from him that he didn't need but was reluctant to throw away, since he knew parts are getting rare. I replaced the crank from underneath without pulling the engine. I got the crank and new rod and main bearings into the engine in August 1997.

In the May of 1998, the engine was running really rough. I checked the compression to find that 90,115,60,50 dry. Anything more than 15 or 20 lbs. difference from one cylinder to another will make an engine run rough. The back two cylinders were doing less than half the work they should. Wet readings were a little higher but not much.

For those who are unfamiliar with compression tests, you remove the sparkplugs, disconnect the coil wire, screw a compression gauge into a sparkplug hole and crank the engine 5 or 6 times. Compression should come up rapidly for the first stroke or two and then stabilize. After checking each cylinder, you squirt an ounce or two of motor oil into each cylinder and take "wet" readings. If the valves are leaking, the added oil will not change the compression. If the rings are leaking, the oil will help to seal the rings and give higher readings.

Since, my readings were not much different, I decided the valves were the cause of most of the problem. I had adjusted the valves within the first six months of buying my Willys, but only the intake valves. The intake valves on an F-head engine are on top and easy to get at by removing the valve cover. The exhaust valves are in the block. There is a cover below the exhaust manifold that allows you to get at the exhaust valves. It is hard to get at the exhaust valves with the manifold in place, but I have told by people that it is possible. It looked to me like it would be too difficult. Since the studs that hold the exhaust manifold to the block were very rusty, I was afraid that I would not be able to get them off. I postponed adjusting my exhaust valves until the engine ran so badly they couldn't be ignored any longer.

I pulled the head, to find a possible small leak in the gasket between 3 and 4. I also pulled the exhaust manifold. My worst fears were realized when the rearmost stud broke off in the block, which added several days to the project. I found some deep vertical groves in #4. The cylinders were bored .030 over. Even if I bored them to .090, those grooves would still be there. I lapped the valves, which brought the compression readings up to 112, 115, 115, 80.

I've checked into having the engine rebuilt. It looks like it will cost between $1000 and $1500, depending on how many parts are replaced. This includes sleeving the cylinders, which involves boring each cylinder oversided, pressing in a steel sleeve, and boring the inside of the sleeve to the precise diameter of a stock cylinder. Since I have pistons that are .030" oversized already, I'll have to replace the pistons.

Rick

11/5/98

![]()

|

|

© Richard B. Grover 1997 to 2006. | Last updated: Friday, February 15, 2002 |