|

|

|

|

|

|

| Off-Road | Highway | Gear Calculations |

I checked with a couple of four wheel specialist shops about possible solutions. I didn't want to launch into a quick fix that would require other compensating fixes. If I put on larger tires, it would increase the distance traveled for the same number of revolutions of the axle, and it would increase the clearance, but then it might require a body lift, or suspension lift, and would require steering modifications. My existing tires (old bias-ply) are about 30 inches. I can't go much over that without hitting the steering connecting rod behind the left front wheel. So tires were not going to solve the problem.

One place suggested ring and pinion swaps. The stock 5.38 gears are a significant limiting factor in the existing setup. The cost of changing them (at the shop) ran to a little over $800. The swap would raise the speed of all the gears. My crawling speed wouldn't be so low anymore. Then I discovered they could only replace the ring and pinion if I had Dana axles. No gears are available for my Timken axle. I'd have to replace the rear axle to change the gears - much more $$$. So I kept looking.

I found another shop that recommended an overdrive. An overdrive was originally manufactured by Warn in the 1960's and 70's. When Jeeps went to newer transfer case, the unit wouldn't fit and the need was greatly reduced with newer transmissions as well, so production ceased. In about 1991, Advance Adapters bought the engineering specs and tools from Warn and began producing the Saturn Overdrive. The overdrive fits between the transmission and the transfer case, in terms of the actual mechanical force linkage. It physically sits partly inside the transfer case and partly hanging out the back. It costs about a thousand dollars, so I waited for a while.

In February ('97), I purchased and installed a Saturn Overdrive in my truck. It took about eight hours, most of which was trying to get the extra shifter lever in place. It seems that the shifter was designed to go into a CJ, and since my truck is a little different, it took some grinding on the transmission, some bending of the linkage, and some bending of the lever.

It works great! I can now drive about 60 mph. I even have been on the freeways around Phoenix several times. There are sections where the speed limit is 75, so I'm still in the slow lane, but I can get places a little faster. And my truck is very stable at 60, maybe ever better than at 45-50.

To keep the engine rpm down for fuel efficiency and less wear on the engine, I use my overdrive whenever I am over about 40 mph and I love my Willys Jeep Truck with Saturn Overdrive!

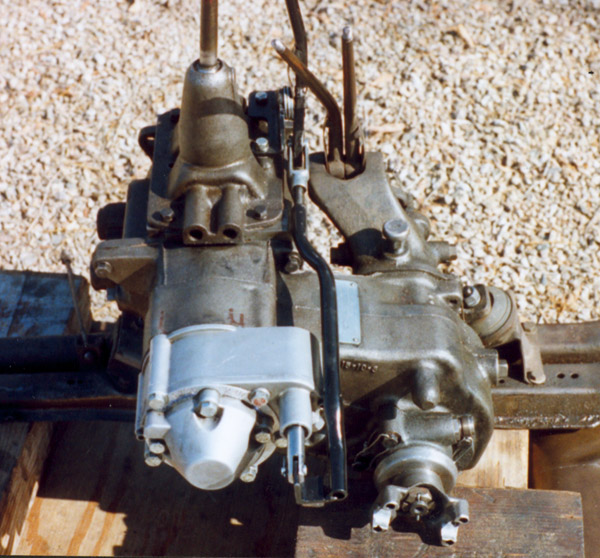

This picture shows the overdrive on the back of the transfer case

when it is out of the vehicle. You don't have to take the transmission

out of the vehicle to install it, but when I took it out for other

reasons, it seemed like a good chance to get a picture. It is aluminum,

so you can see it in contrast to the darker cast iron of the

transmission and transfer case.

As important as the overdrive is for highway

driving, it may be just as useful during off-roading.

We were pacing you at 70mph. Impressive overdrive. I don't have a tachometer, but according to my

calculations, the engine would be turning 3150 rpm to do 70 mph in 3rd

OD. The original owner's manual says the F4-134 in the Jeep Truck

produces 63 hp at 4000 rpm. I've been afraid to take my engine that

high. Anything above 3000 rpm feels stressful.

In March of 1998, 12 1/2 months after installation, the

shifter fork in my Saturn Overdrive broke. As I discovered, this fork is

made of cast aluminum. It is held onto the sliding shaft by a rolled

pin. The break went through hole for the rolled pin, indicating that

this hole is a cause for weakness. I had never seen an aluminum shift

fork before (the ones in the T-90 transmission are steel) but then I'm

not a transmission expert. I've heard that shift forks are often bronze.

I also learned that the Warn overdrives had bronze shift forks.

My brother-in-law Ray (Bubba) has a Saturn overdrive too, and his

shift fork broke after about five months. He is of the opinion that

aluminum is the wrong material. He called Advance, but since he had

lost his sales receipt, he couldn't prove whether or not it was within

the warranty, and AA didn't give him a new fork under the warranty.

I called Advance Adapters, and told them I thought the fork was made of

the wrong material, or at least that if they were going to use cast

aluminum, they needed to increase the size of the arm between the shaft

and the yoke. They said my breakage was a fluke and that they weren't

aware of any problem with the fork. I bought a new fork from them. They

said if I sent the broken fork to them, they would look at it to see if

something could be done about compromising with me on the warranty,

since I was only about two weeks past one year.

I guess I robbed them of the opportunity to learn more of the flaw,

because I never sent it to them. I wanted to photograph it for

this web page, and I thought about using it to make a mold for a casting

of some other material. But before I got lined up with a foundry, I

found a bronze fork from an old Warn overdrive (May 98). It showed less wear

than the one year old aluminum fork. This confirmed my conclusion that

aluminum is the wrong material. The bronze fork is a tiny bit thicker in

the area of the break and it is a tiny by shorter between the shaft and

the yoke.

I was involved with other problems (broken axle, etc.) so I didn't

do anything with the bronze fork for several months. In the late

October 98, while the transmission was out of the Willys for other reasons, I

installed the bronze fork into the overdrive.

Off-Road Update

During spring break (March '97) I took a ride in the Bradshaw Mtns.

Since the overdrive can be shifted in and out in any gear and at any

speed, it is great for splitting gears. Low-range overdrive may sound

crazy, but low-range 1st overdrive is a little higher than low-range

1st, but not as high as low-range 2nd; and the overdrive can be shifted

back to normal drive without the double clutching required to get into

1st while rolling.

![]()

Highway Update

From: John McIntosh

Date: Mon, Apr 28, 1997 10:40 AM

Subject: Overdrive

To: Richard Grover

Cc: Michael Nielsen

![]()

Design Flaw Update

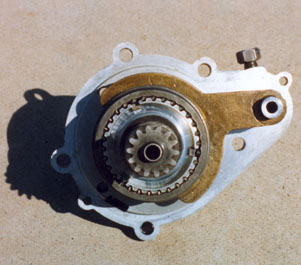

This picture shows the broken aluminum fork next to a bronze fork.

This picture shows a new aluminum fork next to the bronze fork and

the broken aluminum fork. Notice the width of the arm and the placement

of the hole for the pin. It is easy to see the difference, so I don't

think there is much doubt that the aluminum fork is inferior. I have

heard that AA improved the fork but haven't seen the new version.

The bronze fork from a Warn OD fits on a Saturn OD, and seems to

work fine.

![]()

|

|

© Richard B. Grover 1997 to 2006. | Last updated: Thursday, March 1, 2001 |