I first discovered the rear axle on my truck is a Timken in August of 1996 when I was working on the rear brakes. I had pulled the right rear wheel (which is another story) and I grabbed the axle and found that it had noticeable slack in the bearing. Slack in a tapered roller bearing can be eliminated by tightening the nut holding the bearing, but since this was the first time I had been into the rear far enough to get at the bearings, I thought I ought to inspect them to see what kind of shape they were in. I pulled the bearing and found that it was worn and needed to be replaced. I ran down to my favorite 4WD place and picked up bearings (Timken of course) and seals for both sides. When I got home and took the bearings out of the boxes, I found that they were much smaller than the old ones, maybe half as big as the bearings I needed.

I rushed back down to the 4WD place, and when I said these are too small, one of the guys behind the counter wisely uttered "Timken axle." They gave me other bearings, which I compared to an old one, which was in my hand this trip. (Yes, sometimes I do learn form my mistakes.) So I went home and put the new bearings on my Timken axle, which reduced some growling and made it quieter.

I looked up the Timken axle in my service manual, and learned that some of the early trucks had this axle. Many months later I obtained an original owners manual for this truck and found that the Timken axle was the only axle used at that time. Later trucks and wagons had Spicer 41, Spicer 44 (now known as the Dana 44) or Spicer 53. (The Dana Corporation still has the Spicer Axle Division which makes axles for everything from Jeeps to 18 wheelers.) I think the first set of bearings must have been for the most common Jeep axle, the Dana 44. The Dana 44 is the heavy duty axle still available as an option on new Jeeps. And then I got to thinking, if the bearings for my Timken axle are twice as big as the bearings for the heavy duty axles used on new Jeeps, what does that mean about the strength of this thing?

Yes! It must be a monster.

I've heard of people twisting or breaking their Dana 44 axles. I assumed I had never heard of similar failure of a Timken axle because they are so old and rare. But what if I've never heard of a failure because these things never break! What if these are really as tough as the Dana 60 or 70 found in 3/4 ton and 1 ton trucks? After all, this truck was sold as a 3/4 ton, and the difference between curb weight and GVW is over 2000 lbs. [See note below about broken axle.]

What good is an off-road vehicle if it is not tough? As you may remember from my story of Why I love my Willys, breaking a wheel off my Datsun truck started my heart yearning for a better truck. I love this old Willys and the designers (probably all dead by now) who created this Timken axle.

- Rick February '97

![]()

Rebuilding the differential

In April of 1997, while cruising down the freeway at about 65 mph (by

virtue of my Saturn Overdrive) I heard an awful

bang from under my truck. It had been making various unpleasant howls

and whines for a few weeks, and I had just about decided that I needed

to open up the rear differential to see what was going on. I limped on

home, about 40 miles, at slow speed, and crawled underneath to see what

had made that awful sound. I found that the pinion in the rear axle was

loose. I knew I needed to open up that split casing of my Timken axle

and take a peek inside.

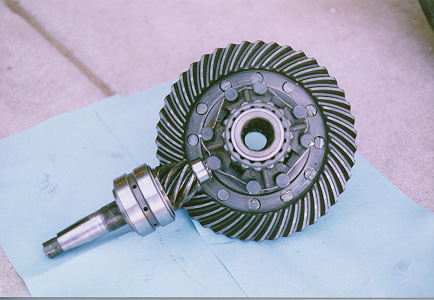

When I got it apart, I found that the pinion had three bearings, or

rather used to have three bearings. Two bearings on the shaft in front

of the pinion gear were still functioning (which had allowed me to drive

home) but a third bearing behind the gear was destroyed. The outside

race was still in the casing, and the inside race was still on the

pinion shaft, but there was nothing in between. There wasn't much oil in

the differential case, but there were metal shreds and a bunch of little

rollers that used to be a bearing. The rollers had dinged up the case in

several places, but the gears (while not in great shape) looked like

they could still be used.

When I got it apart, I found that the pinion had three bearings, or

rather used to have three bearings. Two bearings on the shaft in front

of the pinion gear were still functioning (which had allowed me to drive

home) but a third bearing behind the gear was destroyed. The outside

race was still in the casing, and the inside race was still on the

pinion shaft, but there was nothing in between. There wasn't much oil in

the differential case, but there were metal shreds and a bunch of little

rollers that used to be a bearing. The rollers had dinged up the case in

several places, but the gears (while not in great shape) looked like

they could still be used.

When I went down to my favorite 4WD place, about 12 miles from home, but they couldn't even find a spec. for the end bearing. They said I may have to replace the axle with a Dana 44. Knowing that this replacement would be expensive, and result in a less sturdy truck, I decide to pursue the bearing replacement a little longer. I called Timken in Ohio, and they had specs for all the Timken bearings in the whole truck, but the info was from an old Timken automotive bearing reference book and not from the axle specs. This end bearing was the only one in the whole rear axle that wasn't manufactured by Timken, so they couldn't help me. I learned that the axle business of Timken had been sold to Rockwell many years ago. I called Rockwell in Chicago but they couldn't help me either. It seems that even though they are still a world-class player in the axle business, they have lost the details of this Timken axle manufactured by their axle facilities before they were acquired from Timken.

So I began calling bearing suppliers. No one could find a reference for

this bearing. I took measurements and ask them if they had a bearing

that would fit. I learned that this bearing is a cylindrical roller

bearing, not a tapered roller bearing, and that all bearings are

measured in millimeters. Converting my inch measurements into metric and

talking with the bearing vendors gave me hope that a bearing could be

found, but we couldn't identify the exact part number. Finally a helpful

young man told me to bring what was left of the bearing in and he would

measure it and find me a replacement.

So I began calling bearing suppliers. No one could find a reference for

this bearing. I took measurements and ask them if they had a bearing

that would fit. I learned that this bearing is a cylindrical roller

bearing, not a tapered roller bearing, and that all bearings are

measured in millimeters. Converting my inch measurements into metric and

talking with the bearing vendors gave me hope that a bearing could be

found, but we couldn't identify the exact part number. Finally a helpful

young man told me to bring what was left of the bearing in and he would

measure it and find me a replacement.

I loaded up the axle half with the race, the pinion, and a handful of scrap and headed off to US Bearings & Drives about 30 miles from home. The man measured the inside race and the outside race and said that the width was a standard 15 mm, and the outside diameter was a standard 52 mm, but the inside diameter was just a little bigger than the 25 mm which was the standard match for the other two dimensions. I purchased a bearing and took the pinion to a machine shop to have them cut the old race off the shaft, clean up the end of the shaft so I could get a snap ring on it again, and shave it down so the bearing would fit onto the shaft. They had to grind off 8/1000ths, or something like that. They also helped polish the land for the outer race so that the bearing wouldn't bind when put back in the case.

I decided to replace the front bearings on the pinion as well, since they were quite loose and had gone through the abuse of running without the rear bearing and low on gear oil. Then as I was assembling the rear differential the next day, I discovered damage in the differential side bearings as well. So I replace them too.

While I had the whole back axle off the truck, I discovered that the spring pivot bolts were badly worn and the eye in one of the main leaves of the springs was damaged. I took the spring packs to a local spring shop and had a new main leaf, new bronze eye bushings, and new clips installed. I also got a new rear shackle to replace a badly worn one. It seems the other had been replaced sometime previously.

When I got it all back together again, it ran quieter than ever before. I believe the bearing replacement was long overdue, and the spring repairs were critical as well.

If I keep gear oil in the rear differential, I have high hopes that my Timken rear axle will serve well for another 50 years!

- Rick May '97

|

|

© Richard B. Grover 1997 to 2006. | Last updated: Friday, February 15, 2002 |