Hybridizing Data and Model Driven Approaches for Proactive Production Control

Control

Control

Overall Information

This project will contribute to the national prosperity by investigating a framework for factory-level production control using real-time equipment-level sensing data. Rapid advances in sensor technology, computer-controlled processes, high-performance computing, and internet-of-things (IoT) have the potential to improve the productivity of U.S. manufacturing significantly. However, current production systems remain predominately retrospective and responsive to adverse events because real-time analysis has not been sufficiently integrated in proactive decision support. This award investigates an approach based on hybridizing data-driven statistical methods and with product flow models to address the key challenges in real-time sensing, performance prediction, and proactive control of production systems. The knowledge developed from this research will enhance the understanding of the fundamental principles governing manufacturing systems operations from both theoretical and practical perspectives. The research is integrated with an education plan to enhance education and outreach activities in the minority and underrepresented groups.

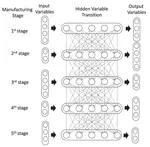

This project supports fundamental research to advance the state-of-the-art in prognostics, data fusion, and real-time production controls at both process and system levels in production environments. The research will investigate a new data-driven approach that combines Bayesian generative models, tensor data analytics, and data-fusion for prognostics to determine a process-level health condition index based on heterogeneous sensing data at different sampling rates. Process-specific health condition information will be integrated with system-level stochastic models for production performance prediction by synthesizing the input from sensor measurements and the output of process-level prediction. Finally, a data-driven sequential decision-making problem will be formulated to derive adaptive control actions that optimize the performance at both system and process levels in real-time. The developed methodology will be tested and validated using data from a small-scale university lab and collaborating industry partners, as well as open data sets published by the National Institute of Standards and Technology.